Features

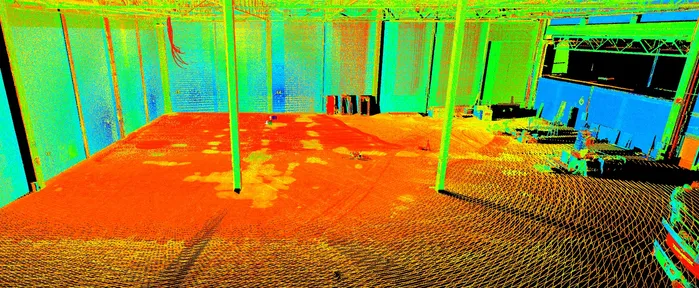

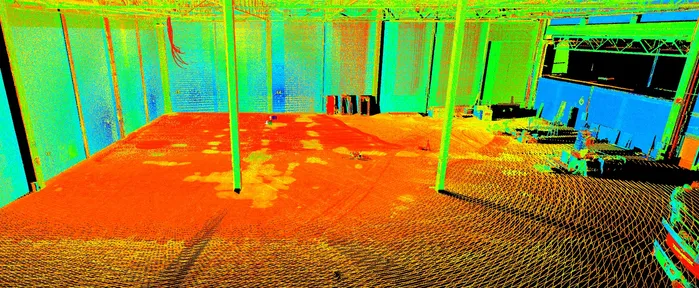

FLAT4™ implements the calculations of traditional floor profilers on digital surfaces created from laser scan data. This virtual profiling is orders of magnitude more effective than conventional devices.

Surface Regularity Report

Surface profiles of industrial floors are to be controlled so that deviations from a perfectly flat plane are limited in accordance with the planned use of the floor. Surface regularity reports are verifying compliance with the relevant floor classification standards. Although there are different types of specifications for floor surface regularity, they are most often defined by 2 main group of properties. Flatness and Levelness.

Flatness is an attribute that helps to understand the relative evenness of the floor and usually measured between 3 or more consecutive points of the floor over a shorter length to be able to identify those characteristics of the floor profile that are making the surface wavy or bumpy.

Levelness will define an elevation difference between two points of the floor a longer distance apart, to give information about the "slope" of an area.

The calculation of floor flatness varies depending on the country and the warehouse operation system. The most commonly used standards were defined in Europe (DIN,EN), UK (TR34), USA (ASTM) and in China (GB/T). These regulations are implemented in many other countries, depending on geographical and economical influences of the above regions and on the warehouse operation system used. Some warehouses combine all or parts of the above standards when regulating their floor to create the most suitable environment for their robots and recking.

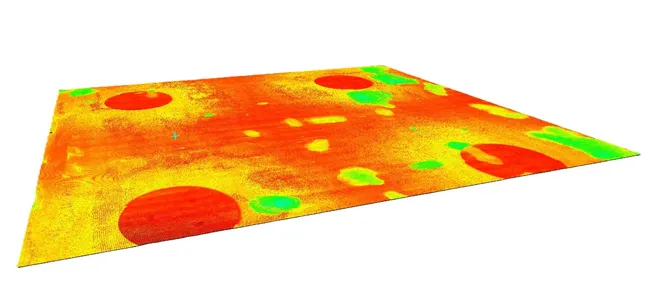

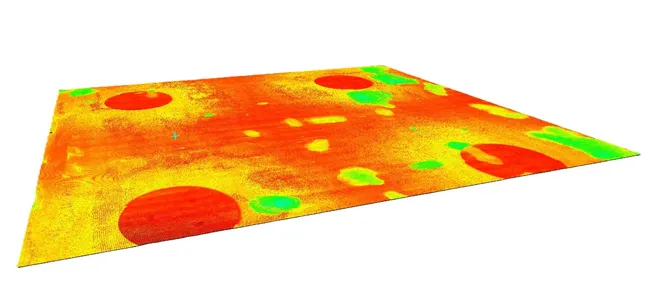

Our SR Reports contain essential statistical records of the floor geometry to help understanding the nature of the irregularities. The documents also include custom scale engineering maps for each type of errors for easy visualisation, as well as detailed AutoCAD files and coordinate lists to help the site team finding the location and the exact size of the errors.

Conventional ways of floor flatness survey require different devices to address different flatness attributes, which means that the survey has to be repeated as many times as there are properties in the specification using different instruments.

FLAT4™ uses laser scan data to calculate the above-mentioned deviations. So the survey is done once, but we can run infinite different types of calculations on the same digital model. Due to our proactive R&D-based approach and modular architecture, new and bespoke standard integration is guaranteed within a business quarter of the release of the specification matrix.

Grinding Plan

FLAT4™ is also capable of running a precisely engineered digital grinding sequence. This will form the base of our Grinding Plan, a scaled engineering drawing along with the coordinate list of the points to grind, which will help the remediating team to target the exact location of the floor and remove only as much concrete from the surface as necessary, optimizing the process both economically and environmentally.Grinding is a sensitive process when the floor is to be assessed against multiple different properties. As soon as someone changes the surface of the floor in order to eliminate a certain type of error, the floor will change in the perspective of all the other irregularities too. If the intervention is not carefully engineered, it can easily result in excessive grinding (removing too much or from the wrong places).

Before handing it out to our client, the grinding plan is applied to the initial digital floor surface by FLAT4™ (Digital Grinding). The result is a new, remediated surface, which then goes through testing against all required properties again. This way we can make sure that, if executed accurately, the grinding will solve all the problems without generating new ones and the floor will definitely pass the final verification.

Download the Whitepaper

Learn how FLAT4™ transforms surface geometry analysis with precision and automation.

Click the button below, and we'll send you the download link straight to your inbox.